Hydrant Guard Manufacturing: Check Valves to Mitigate Water Loss

Hydrant Guard is made in the USA. Read more to learn how Hydrant Guard products are designed, manufactured and shipped to our customers.

Many parts of California, Hawaii and Arizona prefer wet-barrel fire hydrants for their ease of installation and maintenance. But wet-barrel hydrants present one major challenge: when they are sheared (broken) they release massive amounts of water. Wet-barrel fire hydrants have been in use since the 1850s, but there has not been a viable solution to water loss from hydrant damage until very recently. Hydrant Guard is a patented solution designed to keep water in the ground after a wet-barrel hydrant shear.

The amount of water lost from a single shear can range from the tens of thousands to hundreds of thousands of gallons. Taken together, wet-barrel shears result in hundreds of millions of gallons of non-revenue water loss for water districts and cities. While for decades this water waste was impossible to prevent, we now have a solution: wet-barrel hydrant check valves that mitigate water loss.

How Hydrant Guard Took Shape

When Hydrant Guard was first conceived, solutions to wet-barrel hydrant shears were very limited. By and large, the industry accepted hydrant geysers as an unfortunate drawback of using wet-barrel hydrants.

In 2012 Mel Plummer, Hydrant Guard’s founder, set out to test this conventional belief by designing a check valve prototype. He had already been searching for a manufacturing partner for several years when, in 2014, he made contact with the Eagle Group. The Eagle Group is a team of manufacturers based in Muskegon, MI, made up of Eagle Alloy, Eagle Precision Cast Parts and Eagle CNC Technologies. Eagle Group leadership saw the potential for a revolutionary product, and invited Plummer to form a joint venture to bring his product to market.

With the formation of HydrantGuard LLC in 2016, the team continued to refine the design, develop the product line, and manufacture every part here in the United States.

Manufacturing Hydrant Guard Check Valves Today

Today, HydrantGuard LLC is led by the same team that originally developed the part and brought it to market. Design and manufacturing are headquartered in Muskegon, Michigan, and sales and support are located in Los Angeles and San Diego, California.

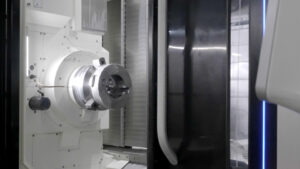

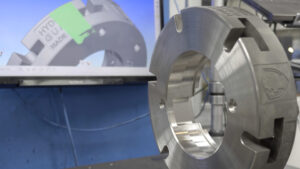

As in the beginning, HydrantGuard LLC sources materials, parts, and accessories through suppliers located primarily in West Michigan. The majority of Hydrant Guard components begin as metal castings, and are then finished through precision machining. As in the beginning, the Eagle Group is Hydrant Guard's casting and machining partner, and Eagle CNC also manages assembly. When you order Hydrant Guard products or request support, you speak directly to a core member of the Hydrant Guard team who can provide updates on shipping status, direct answers to questions about compatibility and customization, and assistance with installation and reset. We pride ourselves on our ability to respond quickly to customer requests, no matter where the call is based.

View the slides below to see the many stages of Hydrant Guard check valve manufacturing:

Our Promise: Quality, Durability and Efficiency

We have spent years refining our hydrant check valve, and we are proud to offer a patented product, made in the USA, that solves the problem of water loss from hydrant shears.

We understand that quality is of the utmost importance, which is why we provide a 10-year warranty on each of our products. This warranty is a testament to our commitment to excellence and our confidence in the durability of our hydrant check valves.

In addition, we provide demos, product customization, on-site testing, and installation support to ensure that our customers have a seamless experience with Hydrant Guard products.

Schedule a consultation now to get help with ordering and logistics, or to see a live demonstration. We are eager to share our innovative, water-saving technology with you.