Hydrant Guard Breakaway Bolts are precision machined from stainless steel. They are modified to specified tolerances in order to shear when hydrant strikes exceed their tensile strength, while minimizing damage to the hydrant and water main system below. All of our Hydrant Guard check valves ship with our breakaway bolts, which consistently exceed the performance of stock bolts.

Due to demand, we now offer Hydrant Guard Breakaway Bolts as a standalone product.

BREAKAWAY BOLT SPECIFICATIONS

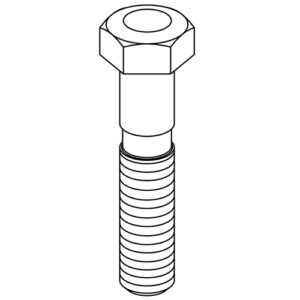

HG1 Style Breakaway Bolts |

|

| Model Number(s) | HGBB-01-625 |

| Configuration | Bolt Cap + Threaded Shaft |

| Material | ASTM F593 Stainless steel |

| Length | 3.5” |

| Diameter | 5/8” |

| Recommended Torque | 50 ft-lb |

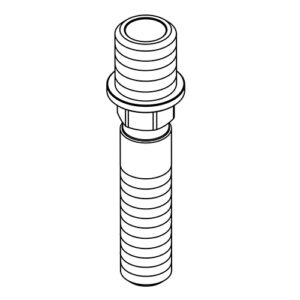

HG2 Style Breakaway Bolts |

|

| Model Number(s) | HGBB-02-625 and HGBB-02-750 |

| Configuration | Threaded Cap + Shaft |

| Material | 304 Stainless steel |

| Length | 2.5”, 3.25”, 4” |

| Diameter | .625” or .75” |

| Recommended Torque | 55-65 ft-lb |

How Do Hydrant Guard Breakaway Bolts Work?

Hydrant Guard Breakaway Bolts secure the hydrant in place during normal operation.

In the event of a strike, Hydrant Guard Breakaway Bolts break when their specified tensile strength is exceeded, preventing damage to infrastructure.

- Each lot has a minimum of 5 bolts tested for tensile strength and yield in their modified state

- Bolts must have tensile strength between 5,500 and 7,000 ksi to pass

- In combination with Hydrant Guard Dual Plate Check Valves and provided gaskets, Hydrant Guard Breakaway Bolts have been tested at pressures greater than 500psi without signs of leakage