The Monster Shear: Las Virgenes Municipal Water District

→ This article is a follow-up to our LVMWD testimonial

Some hydrant shears go relatively unnoticed, causing expenses and headaches for water districts, but no lasting damage. Others—like one that took place in the Las Virgenes Municipal Water District last year—leave a much broader path of destruction. An untamed shear can cause problems for diverted and detoured drivers, for local business, private residents and, of course, the water district left to clean up the mess and handle the red tape, even long after hitting the kill switch on the geyser.

But just how bad can uncontrolled shears get? Here’s an example: when a million gallons of non-revenue water are lost, when the spillage gathers debris, clogging the drains of a local business, when that business seeks damage compensation, and when the terrain around the hydrant erodes to the extent that it needs repairing.

The water-loss consequences of a collision with a hydrant are calculated in thousands or hundreds of thousands of gallons. If it’s large enough, it’s sometimes measured in millions of gallons, or even acre-feet of water loss: 1,000,000 gallons is equal to more than three acre-feet of water, enough water to supply several California households for an entire year.

This is the story of how Hydrant Guard prevented a shear like this from happening.

On a day like any other, Andy Arenas, LVMWD’s Supervisor of Construction got a call from an operator on his staff. He could detect anxiety in the voice at the other end, and soon discovered why: a hydrant shear had gotten out of control. Andy and his team rushed to the site to start the repair, only to discover it wasn’t going to be so easy. A tangled web of pipes and valves, combined with faltering access to mapping technology, made it difficult to identify the correct shut-off valve. The crew worked as quickly as they could and eventually found the right valve to stopper the geyser, but water pressure from the system’s six-inch lines had expelled nearly a million gallons of non-revenue water.

“989,880 gallons is what was lost,” according to the incident report. “It ran for 113 minutes, about 8,760 gallons per minute.”

With the situation finally under control, the LVMWD crew could take stock of the damage: 989,880 gallons of water were lying in pools and running down congested drains. The freeway was flooded and backed up. Down the street, the parking lot of a local business was swamped. And the fallout didn’t end there: shortly afterward, the proprietor of the business sought compensation for the damage. Sections of the surrounding hillside were eroded and in need of repair. All in all, the incident led to over $13k in water loss and labor, not including the payout against, and the resources spent, on settling the damage claims.

Fast forward a year: Andy received another call. The same hydrant was bowled over again. He didn’t detect anxiety in his colleague’s voice, but his instinct was to rush over to the site all the same. On arrival, the scene was calm (and dry) – nothing but a signal spray coming from the Hydrant Guard check valve.

The crew reset the Hydrant Guard valve and re-installed the hydrant within a few hours. The total loss? A breakaway-bolt kit, 5 gallons of non-revenue water and a couple man-hours to reset the hydrant and check valve. No erosion. No damage claims. As expected, Hydrant Guard went off without a hitch, illuminating the stark contrast between a protected and unprotected shear, and giving Andy’s team that evidence they needed to champion Hydrant Guard to the other stakeholders in their district.

Whenever a new product is deployed, it usually has to be forced through a good deal of administrative friction as skeptical stakeholders weigh costs against benefits. Although Andy and his team were bullish on Hydrant Guard’s potential, the new product still needed approval for widespread deployment. This incident provided the finance department before/after Hydrant Guard statistics that spoke for themselves. As for the water conservation team, they were eager to adopt a technology that would show their residents they were doing everything in their power to avoid water waste.

LVMWD’s motivation to protect as many hydrants as possible is stronger than ever. They are including Hydrant Guard on most new hydrant installs with long-term plans to have 75% of their assets covered. The before-and-after picture brought Hydrant Guard’s value into focus, which made the incremental cost of including Hydrant Guard on new hydrant installs easy to justify.

With years of experience in the water industry, Andy Arenas approaches new products carefully—skeptical, but open to innovations that deliver real value to his district and its ecosystems. That’s why, at LVMWD, Hydrant Guard isn’t just a smart investment—it’s part of their sustainability roadmap. Looking ahead, Andy hopes to see water-saving devices like Hydrant Guard extending beyond his community: “I won’t be surprised in the future when I’m driving through other cities, other states and see Hydrant Guard.”

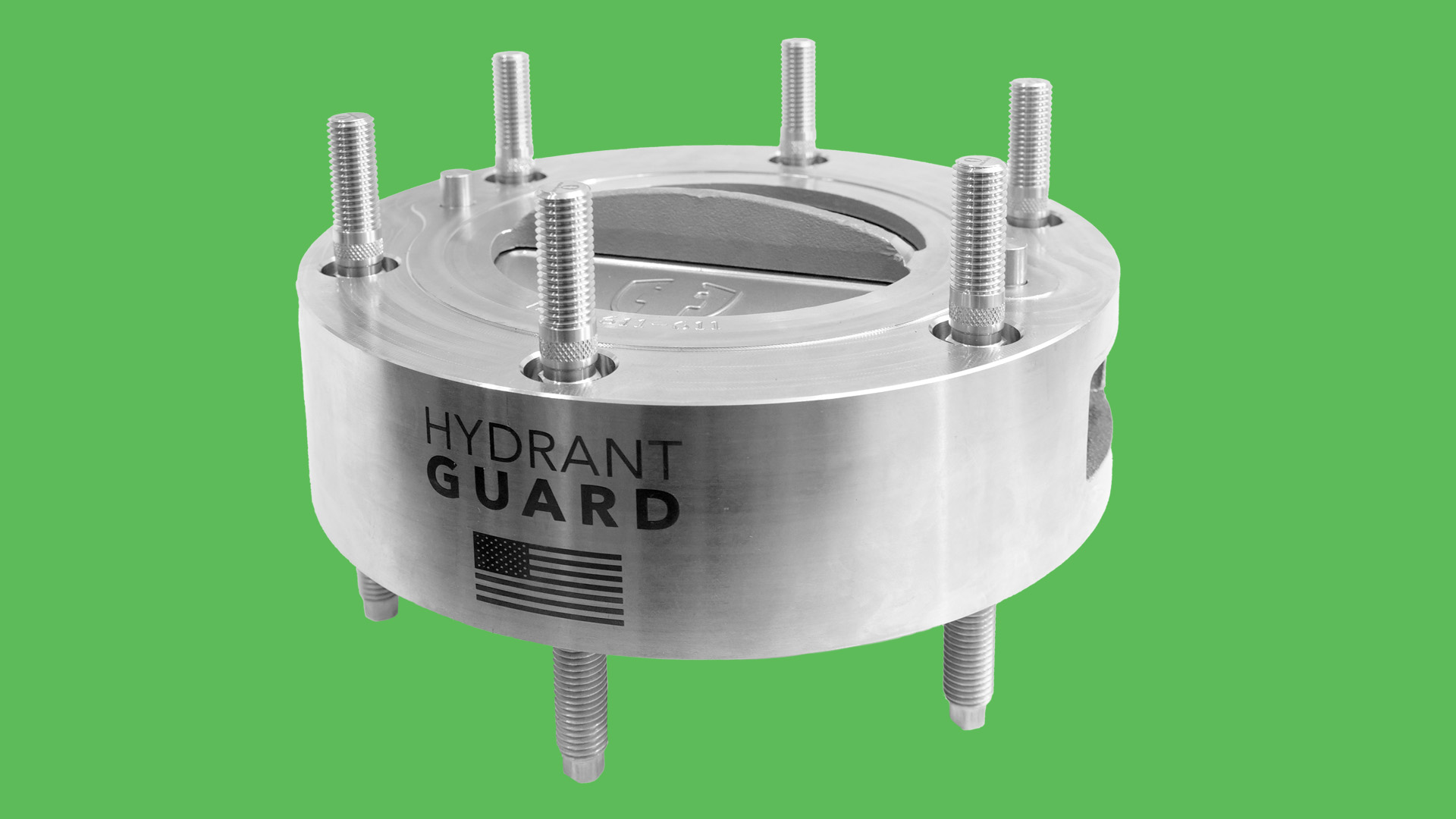

Above: LVMWD operator installing Hydrant Guard HG2 check valve